Earthquake Resistant Engineering

To ensure the structural safety under large earthquakes, our research is aimed at establishing comprehensive seismic design methodologies as well as characterizing earthquake response characteristics and failure mechanisms of structures through analytical and experimental investigations.

The emphasis is placed on the collapse mechanisms and associated behaviors of structures and their members under large cyclic loading. Experimental techniques integrated with stable control algorithm is being developed in order to simulate the seismic behavior of structures under large deformations. The outcomes of our research would motivate advances in seismic design practices.

Academic Staff

Yoshiki IKEDA

Professor (Disaster Prevention Research Institute)

Professor (Disaster Prevention Research Institute)

Research Topics

● Earthquake-resistant structure, base-isolated structure and structural control

● System identification for building structures

● Structural health monitoring

Contacts

Uji Campus, Main Building S-307D

TEL +81-774-38-4086 / FAX +81-774-38-4334

ikeda.yoshiki.6r@kyoto-u.ac.jp

Masahiro KURATA

Associate Professor (Disaster Prevention Research Institute)

Associate Professor (Disaster Prevention Research Institute)

Research Topics

- Autonomous Structural Integrity Assessment System for Steel Structures

- Heuristic Damage Detection of Structures Using Model Updating Approach

- Cyber-enabled Wireless Monitoring System for Large Scale Structures

- Structural Members Capable of Self Damage-Prognosis.

Contacts

Uji Campus, Main Building S-308D

TEL: +81-774-38-4084

FAX: +81-774-38-4334

E-mail: kurata.masahiro.5c kyoto-u.ac.jp

kyoto-u.ac.jp

Research Topics

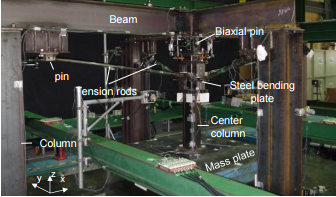

Experiments and Analyses on Behavior of Structures to Complete Collapse

In modern seismic design, the performance-based design philosophy has been adopted. According to this design philosophy, structures are designed to satisfy a set of performance objectives so as to maintain functionalities, limit structural damage, and ensure the life safety during earthquakes.

To ensure the life safety, it is important to quantify the collapse mechanism as well as strength and deformation capacity of structures. Here, collapse is defined at the stage in which the structure is no longer capable of sustaining gravity loads. The collapse limit is quantified experimentally.

Figure 1 Loading Test of Full-Scale Moment Frame

Development of Low Disturbance Seismic Rehabilitation Techniques

Structurally-deficient steel frames need the increase of the earthquake-resisting capacity.

This research aims to develop resource-saving seismic rehabilitations which satisfy the following design requirements: (1) to reduce demand at critical structural elements that governs the deformation capacity of the entire frame; (2) to increase the initial stiffness and strength of original frames, and energy-dissipation capacity; (3) to install the system without disturbing the architectural plan by keeping visibility.

We develop seismic rehabilitation techniques that do not require the use of heavy construction equipment and fire by combining light-weight steel elements and energy-dissipating elements. Also, for historical buildings and ultra-long-life structures, seismic retrofit methods with the limited use of technologies and material that will exist in hundred years from now are explored.

Figure 2 Shake Table Testing of Low-Disturbance Seismic Rehabilitation Technique

Advancement of Structural Condition Monitoring Methods for Post-Earthquake Building Inspection

Seismic damage assessment for building structures has received much attention due to a significant demand for quick recovery of functions of cities and communities after large earthquakes.

For assisting the current visual-based quick inspection process, our group works on the development of prompt and effective seismic damage monitoring techniques for buildings by utilizing smart sensing, wireless sensor networks, information processing technologies, and seismic damper capable of condition assessment.

Meanwhile, with the aid of model-updating techniques and probabilistic seismic hazard analysis, we intend to provide decision-support index and information that are friendly to structural engineers and buildings’ stakeholders.

Figure 3 Verification of wireless damage evaluation system in 18-story steel frame shake table test