Built Environment Materials and Structural Systems

Our laboratory focuses on structural members, interior and exterior materials, mainly reinforced concrete members. We are working to evaluate and predict the performance and condition of materials from various information such as constituent components, void structure, and the behavior of water in the material, and apply it to the durability evaluation and maintenance of buildings.

As part of this effort, we are promoting joint research with researchers in different fields such as nanotechnology and microbial ecology, and are also actively working to improve sensing technology for information that has not been acquired or has not been easily acquired in the construction field.

Academic Staff

Atsushi TERAMOTO

Associate Professor (Graduate School of Engineering)

Research Topics

- Durability design and maintenance of reinforced concrete buildings

- Development of non-destructive diagnostic technology utilizing microorganisms community and semiconductor chemical sensors

- Evaluation of CO2 fixation in concrete structures

- Aesthetic evaluation of interior and exterior materials

Contacts

Room 486, Bldg. C1, Katsura Campus

TEL: +81-75-383-3286

E-mail: teramoto![]() archi.kyoto-u.ac.jp

archi.kyoto-u.ac.jp

Research Topics

Relationship Between Moisture, Volume Change, and Deterioration Mechanisms in Concrete

Focusing on porous building materials such as concrete and mortar, we are conducting research to clarify various deterioration mechanisms that degrade the performance of buildings. We also aim to develop diagnostic and preventive techniques.

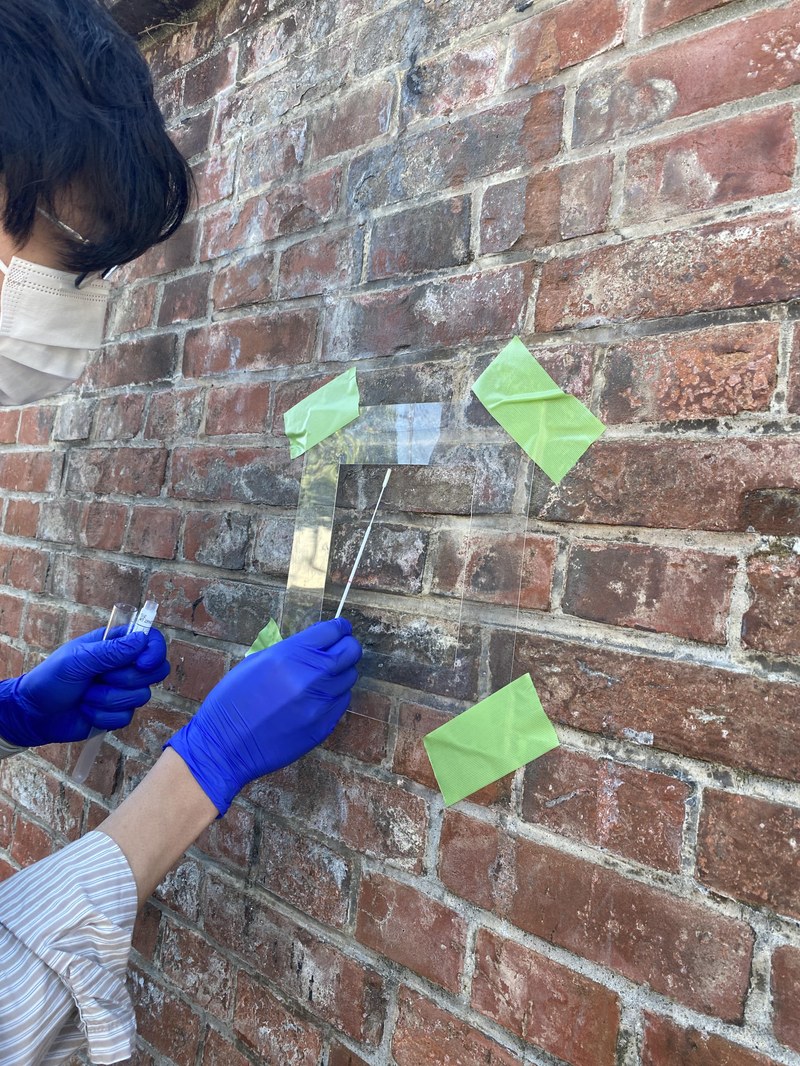

Evaluation of Building Material Conditions Using Microbial Diversity Indices

This research proposes a method to assess and predict concrete deterioration in aging concrete structures using microbial diversity indices.

Almost all forms of concrete deterioration involve changes in moisture content, pore structure, and ionic composition of pore solution. We analyze microbial community types, quantities, and composition ratios that respond to these factors, and evaluate them using diversity indices.

Development of an Embedded pH Sensor Using a Semiconductor Chemical Sensor

Currently, CO₂ fixation in concrete structures is estimated using simplified methods based on carbonation depth and degree. However, measuring carbonation depth is destructive, and the degree of carbonation can vary due to environmental factors.

This study proposes a method to directly measure pH reduction in concrete caused by carbonation using a semiconductor chemical sensor (LAPS), and to estimate CO₂ fixation based on the measured pH.

Modeling the Effects of Surface Finishing Materials and Cracks on Carbonation in Concrete Structures

As part of efforts to combat global warming, the concrete field is exploring CO₂ fixation through carbonation reactions between atmospheric CO₂ and Ca(OH)₂ or C-S-H in concrete, in addition to using low-emission materials.

Although prediction methods using carbonation degree and depth have been proposed, the concrete surfaces of many RC buildings are finished or have microcracks.

This study develops prediction methods for CO₂ fixation that account for these characteristics of RC buildings.

Monitoring of painted concrete members

Monitoring of painted concrete members

Development of Quantification and Control Methods for Biological Staining on Building Materials

While aesthetics is an important factor in building evaluation, studies on its relationship with other performance aspects like mechanical strength are limited.

This research focuses on biological staining on building materials, investigating its causes and how such phenomena may affect other performance characteristics.

Ring-shaped stain on a gypsum board ceiling

Ring-shaped stain on a gypsum board ceiling

Development of Methods to Control Indoor Microbial Environments Through Building Material Selection

Microorganism-derived components such as mold, bacteria, and viruses can reach deep into the respiratory system, potentially causing allergic reactions or severe health effects. However, few studies have addressed how to suppress the growth of pathogenic microorganisms from a hygienic microbiological perspective.

This study focuses on the types of materials used in buildings, aiming to clarify material-related factors (mainly pore structure, surface moisture content, and pH) that influence the microbial environment, and identify materials and environmental conditions that inhibit pathogen growth.

Our ultimate goal is to establish a foundation for using beneficial microbes to improve living environments.

Cracks around rebar caused by autogenous shrinkage

Cracks around rebar caused by autogenous shrinkage Differences in microbial diversity in mortar with varying porosity

Differences in microbial diversity in mortar with varying porosity

Microbial sampling in a brick building

Microbial sampling in a brick building